Well to start with all this we must know what an Arduino UNO.

Arduino UNO is a microcontroller plate hardware is free, that is, we can make copies of it because it was invented as an educational support. It incorporates a reprogrammable microcontroller and a series of pin female (which are attached to the E/S of microcontroller pin) for connecting there easily and comfortably different sensors and actuators.

When we talk about hardware board, we are referring specifically to a PCB (Printed Circuit Board). The PCB surfaces are made of a nonconductive material (typically fiberglass resin, ceramic or plastic) laminated on which conductor tracks (copper) materials appear. PCBs are used to electrically connect, via the conducting paths, different electronic components soldered to it. A PCB is more compact and stable way to construct an electronic circuit.

All Arduino microcontrollers are the type AVR architecture developed by ATMEL. Mainly Arduino Uno has the ATMEGA 328P, and also accurate to schedule the ATMEGA16U2 USB, a USB to TTL converter.

In this picture we can see the step ATMEGA328P and identify ports for programming.

Then the ATMEGA16U2.

Once the introduction of what the microcontroller, we need to know what leads a microcontroller system inside.

We have understood what we will do, let's start making our Arduino UNO as REV.3, so we need the schematic we can consult the web

http://www.arduino.cc/en/uploads/Main/Arduino_Uno_Rev3-schematic.pdf

With the Proteus software we carry out our schematic. As stated are other entries of how a circuit is done with Proteus, I leave the link so you see it.

http://elblogdejosewa.blogspot.com.es/2015/02/creating-simple-pcb.html

We started with the ATMEGA328P.

We continue with the ATMEGA16U2.

Then powered.

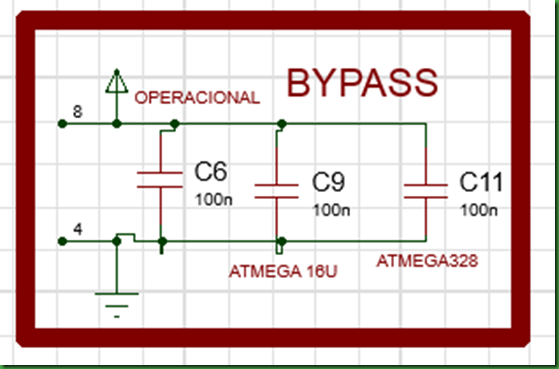

And we finish with the bypass.

Once you have connected components well, we're going to ARES.

If we want to do with the size it is Arduino Uno to place him shields, we must continue indicating the next image.

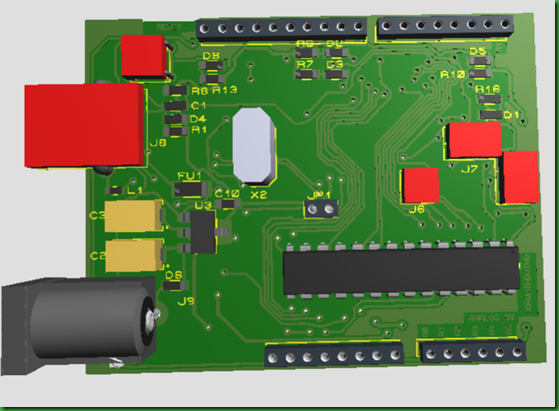

This will be the view of the plate.

Once our board need to buy components. As we have learned to make the footprints of the components and put the price should not change much, while suppliers do not sell a single component, and must buy minimum lots, I attached the web where you can make purchases.

http://es.rs-online.com/web/

http://es.farnell.com/

In the part of Bill of Materials will leave everything it takes to make our Arduino RS as references are those that have put. I attached a cut image as displayed.

Once they reach the components, we will get to work for the board, in Proteus ARES have an option called Generate Gerber.

We see this message.

We say yes, because we have ensured that we have not left any clues unbound or no potential conflict between tracks between tracks or between components.

It will do the test.

And this should appear and click close, if not put PASSED must correct the error.

We will get this screen and choose according to what we will use as a machine for our board. In my case is CNC so we will choose this.

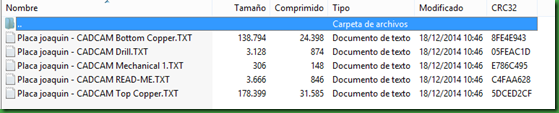

We chose the location and keep it in a .ZIP, press ok and our archive should leave it.

We get the file to a pen and go to the computer that runs the CNC. The model is as follows.

The protocol we have is us a folder with students on the computer in which consist our plates and a excell document the use we give to the milling and drilling, but later I show the type of drill.

Although we have done what the Gerber, we must tell our CNC parameters that through Circuit Cam program transforms them into a document type that if you understand the CNC for that I leave a video explaining how.

Then we have a video of how to use the Board Master and put strawberries and drills, is now her time to explain that strawberries have given us for the plates are essential and are Orange 0.2mm 8mil for tracks to be skirting finer things and the abode of 1.00mm is the END thousand which is to finish and leave things ready. Which comes with green border are bits of different sizes and then we have one that is cut is called yellow Contour router.

A video of how to get bits and starts the process of making changes via attached.

The next step is to perform milling botton but clear before we know if the drill is up for it we go to the plate and choose with left mouse button a small part of a track that is little conflict and give the chosen tool in the photo.

We give Start and hope to do the selected track, we take the microscope and see.

If we see that the track is in the regulatory measures and are isolated from each proceed forward as shown in the video, if you had the following must regulate to come down here deepen strawberry or strawberry much to climb. One little penetration failure strawberry attached.

We go to the CNC and give roulette drill. Do this until you get it right.

Now enjoy the video of how to do the milling botton.

After milling botton we have to flip to the plate and do the milling top. Video of how the operation is attached.

Once made the top milling cuttingoutside have to do is make the cuts to remove the plate as will be explained later.

Para finalizar tendremos que apagar la CNC, apagar el ordenador y aspirar las virutas de la zona de trabajo dela CNC.

Once we have left to do off the cookie, for this we follow the next video.

Attached are photos of several plates.

Now after making the PCB is put track changes that are made riveting. Attached are photos of the process.

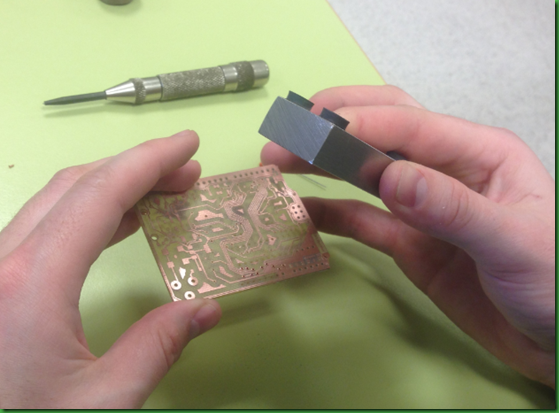

In the next picture we do it is support him and then turn around and drive home to the punch.

After riveting the entire board we have to take the components and soldering, as I have no explanatory video I will attach a video from my partner John Biondi as SMD welding.

And as a final picture welding plate is attached.

To download the files from all the practice you must click on the picture below.

Thank you for this huge work!. Itś not very often to find an Arduino Shield proteus PCB on the web and I am very thankful for this.

ResponderEliminar

EliminarNothing, I will upload new things.

how to get atmega16u2 in proteus?

ResponderEliminar

ResponderEliminarExcellent work but I can not open the file of poteus, which version do you have?

8.1

ResponderEliminarFunciona bien el arduino este?

ResponderEliminarIt works well this arduino?

ResponderEliminarSi, de todas formas si quieres hacerte uno, puedes quitar componentes y programarlo por el puerto icsp, o con otro arduino y por puerto serie. Así podrás otras cosas en la placa. Si tienes alguna duda me lo dices y te ayudo.

ResponderEliminarPodrías pasarme tu correo para poder contactar? Muchas gracias.

EliminarJosewapepewa@gmail.com, lo que si me gustaría, si fuera una duda que pudiera servirle a alguien que vea el blog, que lo plantees aquí, así nos nutrimos todos.

ResponderEliminarcan you send me arduino uno pcb layout file which is in proteus

ResponderEliminar